Your Cart is Empty

Save $100 on every egress window kit with well through the end of January. Apply Discount code "BringTheLight" in shopping cart.

Save $100 on every egress window kit with well through the end of January. Apply Discount code "BringTheLight" in shopping cart.

Galvanized Window Wells - The Best Choice For Your Egress Window

by Theo Stephens May 31, 2022

Aside from choosing the type of egress window, the size, trim kit, and other related items, you also need to determine which type of egress window well you want to install. A window well is essentially the hole that has been dug in front of your basement egress window. Soil tends to move, may it be because of the elements, roots, earth movements, or other factors. To keep everything in place, you need to add a “window well wall,” generally referred to as a window well.

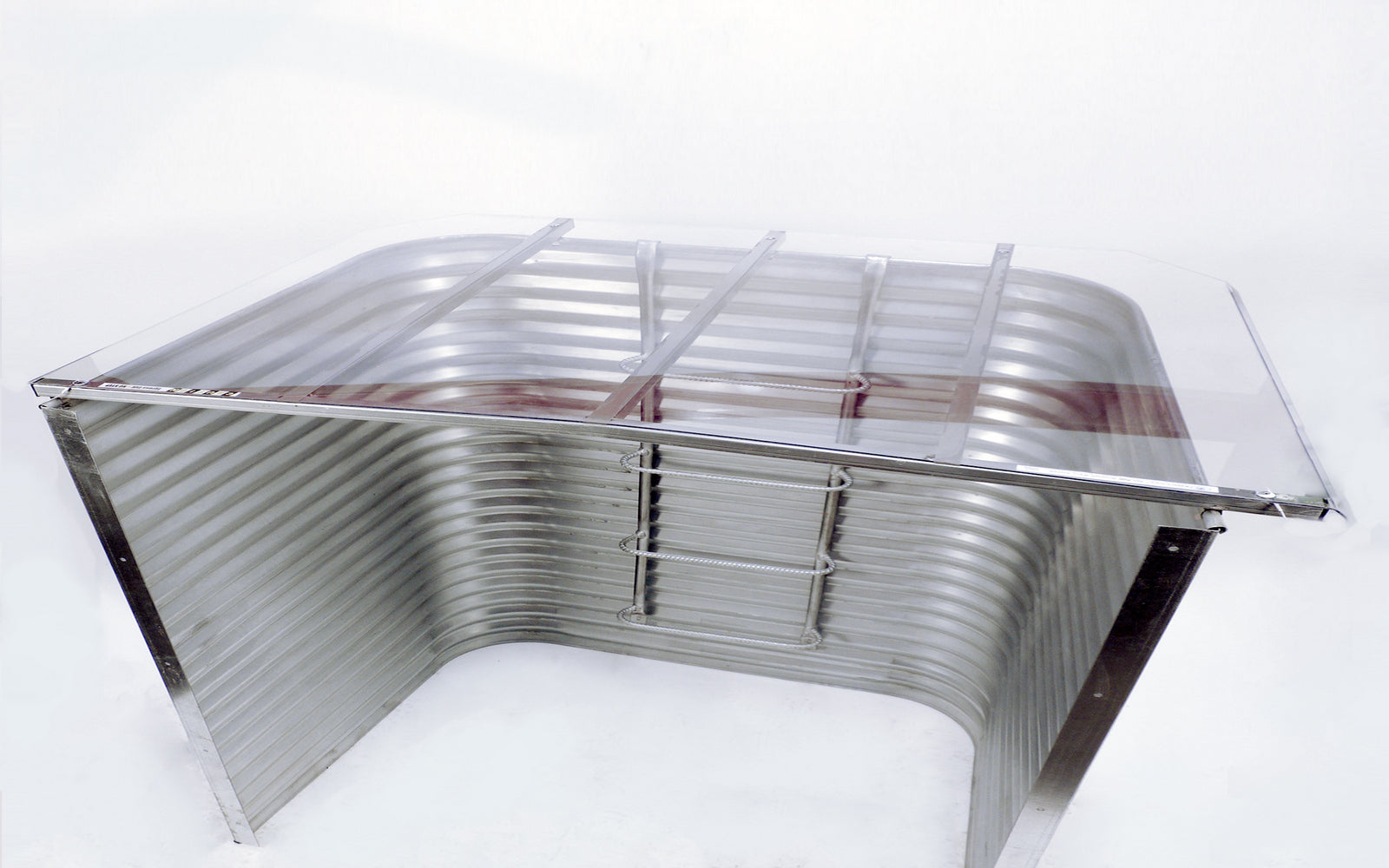

How do you choose the best window well for you? There are different materials you can choose from. Frequently, window wells are made out of corrugated metal, masonry, plastic, or pressure-treated wood. Each has several factors to consider outside of appearance. If you have multi versus single piece wells, you will ultimately have to deal with cracks and water intrusion due to settling, rain, or ice exposure. Concrete wells are more challenging to install. Metal single-piece wells make installation a lot easier and are more leak-proof than their counterparts.

If corrugated metal is used, the components are usually 20 or 18-gauge steel sheets that are galvanized. The gauge number refers to the steel thickness, an 18 gauge steel sheet is approximately 1/20 or 0.05 of an inch thick. You want to make sure that your well is made of 18 gauge steel as it is thicker and more durable. But even thicker steel, if left untreated, wouldn’t last very long when exposed to the elements. Through a process called hot-dip galvanizing, the manufacturer will apply an added protective layer to ensure your window well doesn’t rust away.

What is Galvanized Steel?

Egress window wells will be buried in the ground, with one side exposed to dirt and the other exposed to the rest of the outside elements. The steel has to be treated with corrosion protection before installation to ensure that it keeps a nice and clean appearance not just for the first few weeks but for years, if not decades, to come. One of the most frequently used procedures is galvanization.

Galvanization

Patented on May 10th, 1837, by Stanislas Sorel, a French engineer, galvanizing is a process in which the metal, either steel or iron, is coated with zinc. One of the most common techniques is hot-dip galvanizing.

This technique requires that the metal structure, in this case, the window well, is dipped into a bath of molten zinc. The molten zinc has a temperature of 840°F (450°C), and it does not just coat the metal; it chemically bonds with it through a chemical reaction that takes place once exposed to the atmosphere. The zinc (Zn) reacts with oxygen (O2) and turns into zinc oxide (ZnO), which then reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3) finally. This process allows the underlying metal to be protected against corrosion even if the galvanized coating is damaged, as the zinc can continue to protect the metal through galvanic corrosion. The zinc coat acts as a galvanic or sacrificial anode.

This method is an established practice for metal structures exposed to the elements but where it is not feasible to use stainless steel, making it ideal for egress window wells.

How long does galvanized steel last?

According to the American Galvanizers Association, you can expect galvanized steel your window well is made of to last for an average of 75 years, depending on the soil conditions in your area.

You may also come across the term G90 galvanized steel, which speaks to the thickness of the actual coating that is applied during the hot-dip galvanizing process. G90 is the designation for a 0.9 oz/ft2 coating thickness and provides a longer life span for your product than a G60, G40, or G30 coating, which offers a lesser thickness.

Does galvanized steel rust?

Even galvanized steel can rust after decades of exposure to the elements. Factors that might cause or speed up the corrosion are exposure to electrolysis (Electrolysis is the passing of a direct electric current through an electrolyte producing chemical reactions at the electrodes and decomposition of the materials), acidic weather conditions, and salty or marine environments. The high electrical conductivity of the marine environment causes solid zinc to convert into soluble zinc, which washes away.

Can you paint galvanized steel?

The short answer is yes, but painting it yourself is not ideal as you might encounter easy peeling or difficulties with getting the paint to stick to the metal. Most galvanized steel window wells are left untouched to provide low maintenance and decades-long use.

You can also buy galvanized window wells that are coated with paint-like enamel. While the extra layer gives your window well a little more protection, it is an added manufacturing process on top of the hot-dip galvanizing. This procedure is done in two separate facilities, which means additional transport and labor, resulting in a higher purchase price for you than the non-enameled version. While some homeowners may like the aesthetic of a white enameled window well, the enamel can get scratched. Touch-ups may be somewhat unsightly.

Longevity, Low Maintenance, and Ease of Installation

If you are looking for an easy installation process, the most extended service life, and the least maintenance, an 18-gauge, G90 galvanized steel window well should be your top choice.

One crucial point in your window well research is to check for the best craftsmanship. At Bright Idea Egress, we only offer the highest quality of galvanized window wells when you order your Egress Window Kit with ExoFrameTM and Window Well.

Contact one of our specialists for more information at 303-761-3730 today to find the right egress window with window well for your basement.

Also in Egress Window News

The New Way to Install Egress Windows — Video How-To Comparison

by Theo Stephens December 13, 2023

Theo Stephens compares the ExoFrame egress window kit system to the old way of installing basement escape windows

Read More

How Much Value an Egress Window Adds to Your Home: 2022 Update

by Theo Stephens October 11, 2022

An egress window project remains a strong bet in 2022 to boost the livability and value of your home. We see a strong appetite for this project from DIY homeowners as well as basement remodelers and other installation specialists.

Read More

Installing Egress Windows - A Lucrative Add-On To Your Home Improvement Services

by Theo Stephens September 22, 2022

Are you contemplating expanding your contractor, window installation, or landscape design business and offering more services? Adding egress window installation might just be what you are looking for. Installing egress windows dovetails nicely with landscape design contracting and concrete cutting.

Read More